Production of graphene

- font size decrease font size increase font size

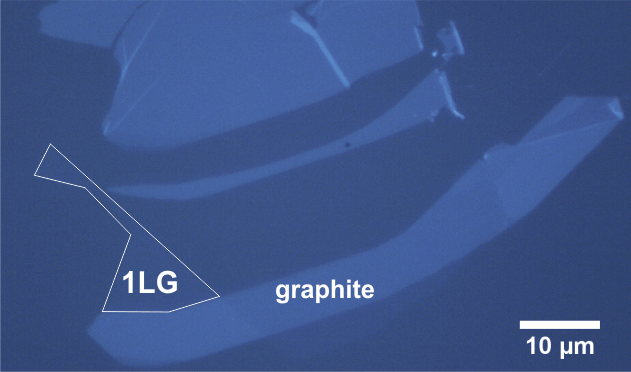

Mechanical exfoliation of Graphite

The samples of graphene are produced by using the method of mechanical cleavage of graphite (scotch tape method). The tape is placed on the top of SiO2 or various polymeric substrates. Peeling off the tape, graphene flakes are transferred on the substrate. From optical microscopy we locate the graphene flakes due to their contrast and measure their dimensions. Finally, using Raman spectroscopy the number of layers of the graphene flakes is identified.

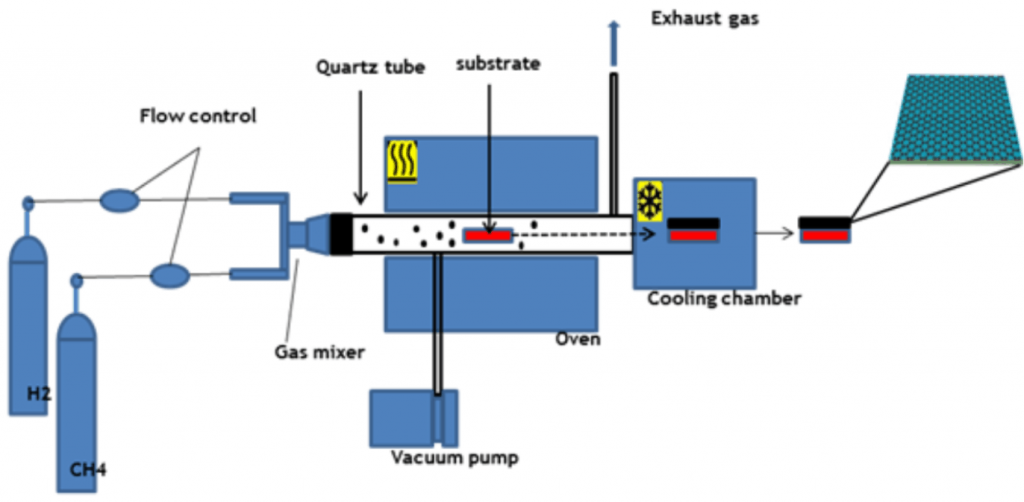

Chemical Vapour Deposition (CVD)

The research team at FORTH/ICE-HT has sound expertise in the synthesis and characterization of graphene. At the moment graphene production is carried out using two independent CVD systems. The first system includes a horizontal quartz reactor (1200mm length, 40mm inner diameter) and a three-zone split-type tubular furnace. The second system includes a vertical quartz tube (1200mm length, 78mm inner diameter) and a heavy-duty three-zone furnace with pc-based control of the gas flow using electronic mass flow controllers. The two CVD systems are capable of using many different types of substrates with dimensions varying from a few mm to 230mmX600mm sheets. Methane and commercial camphor are mainly used as carbon source, while nitrogen, hydrogen and ferrocene are used as gas feeders or catalysts. The CVD lab at FORTH/ICE-HT is hosted at a specially designed room with modern exhaust and ventilation ducts, ensuring the safety of the personnel.